Description

Specifications

Material

Structure and components made entirely of aluminum, stainless steel bolts and nuts

Max Snow Load

Can be designed for any snow load (up to over 100 PSF)

Max Wind Load

Can be designed for any wind load (up to 180MPH+/290 km/h+)

Tilt Angle

Typical 5 to 10 degrees (can virtually be designed to any angle)

PV Panel Orientation

Landscape on rails, portrait is possible, but will not be sealed

Solar Panel

Any monofacial or bifacial PV panel with or without a frame (glass laminate), optimized for bifacial

Sealed

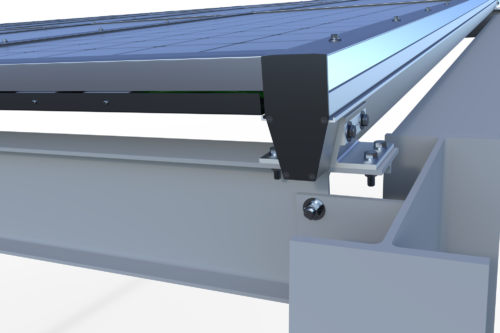

Water management with rubber seals (laminates).

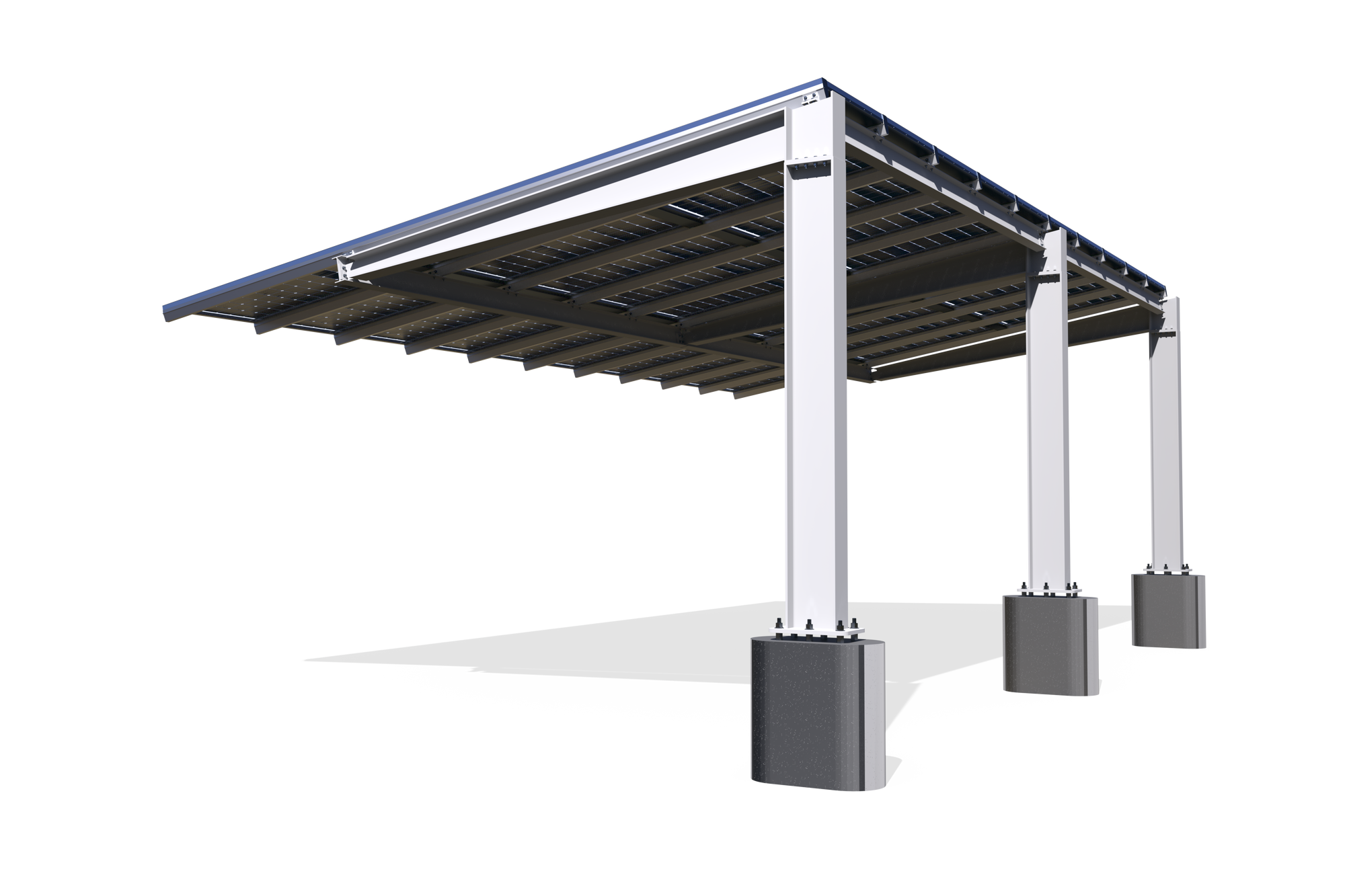

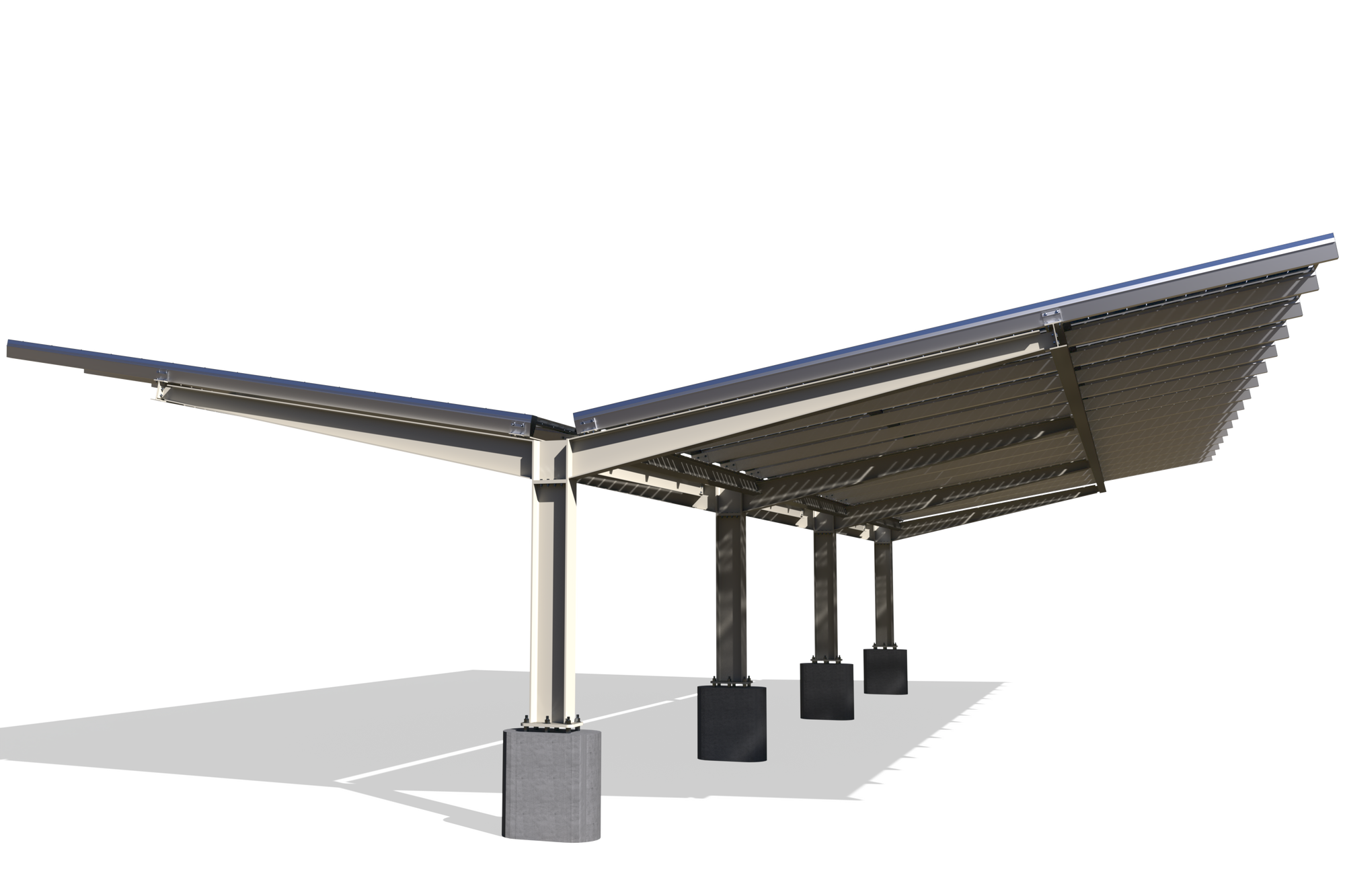

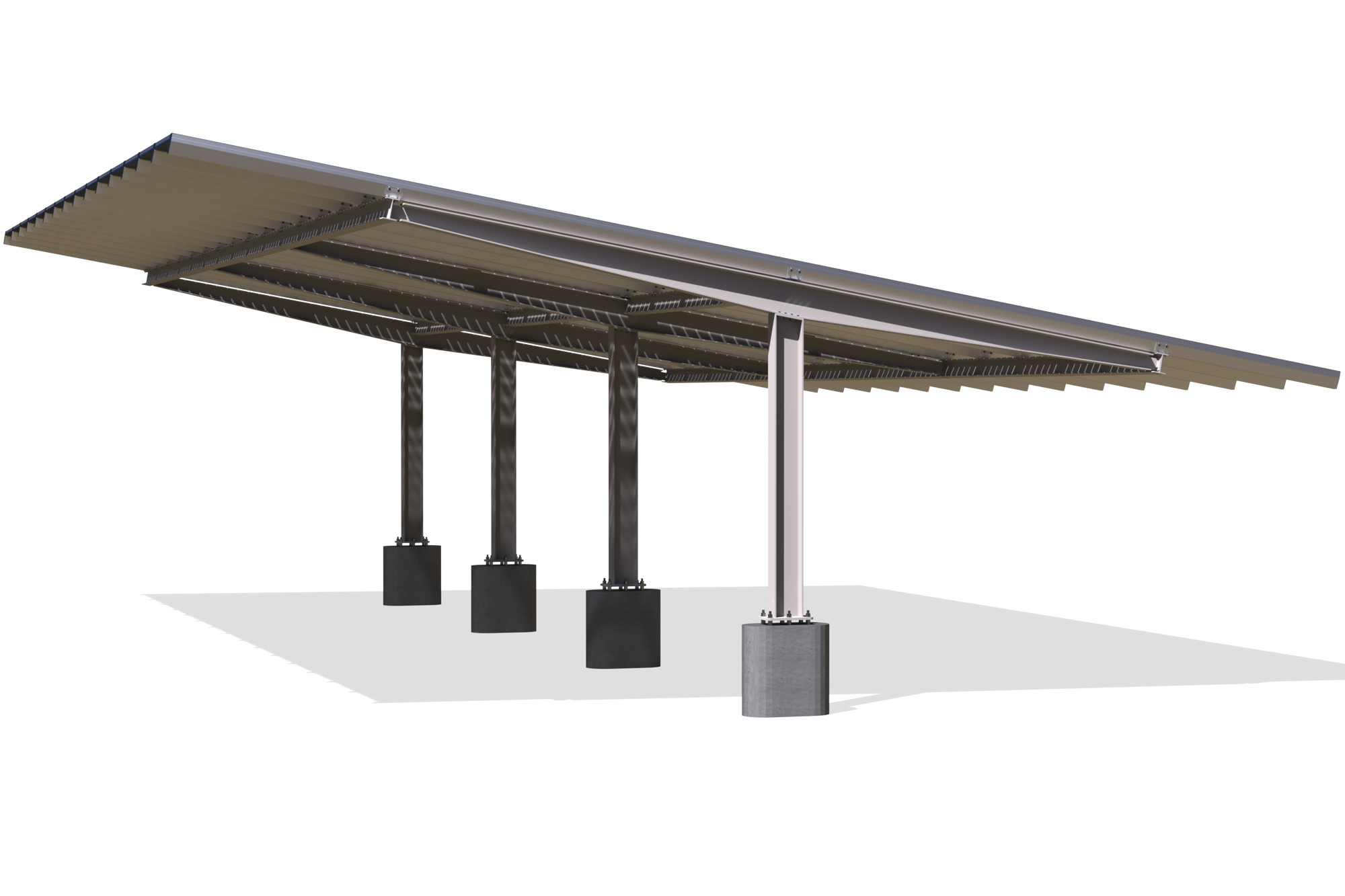

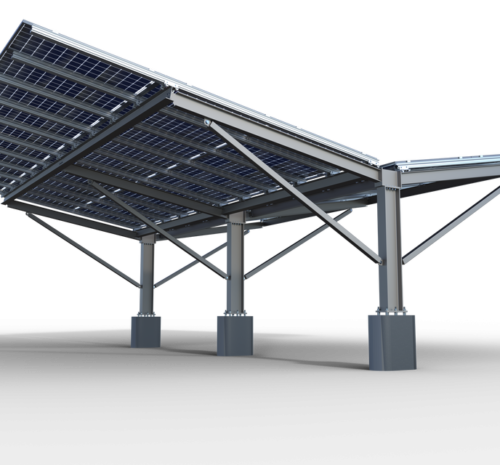

Configuration

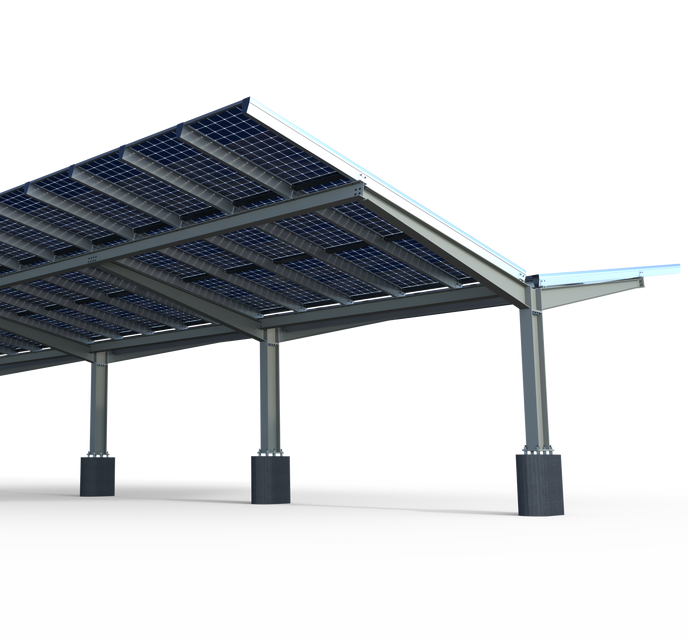

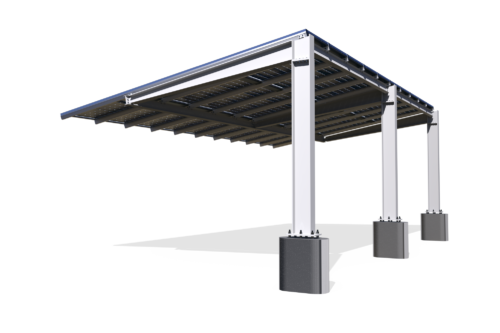

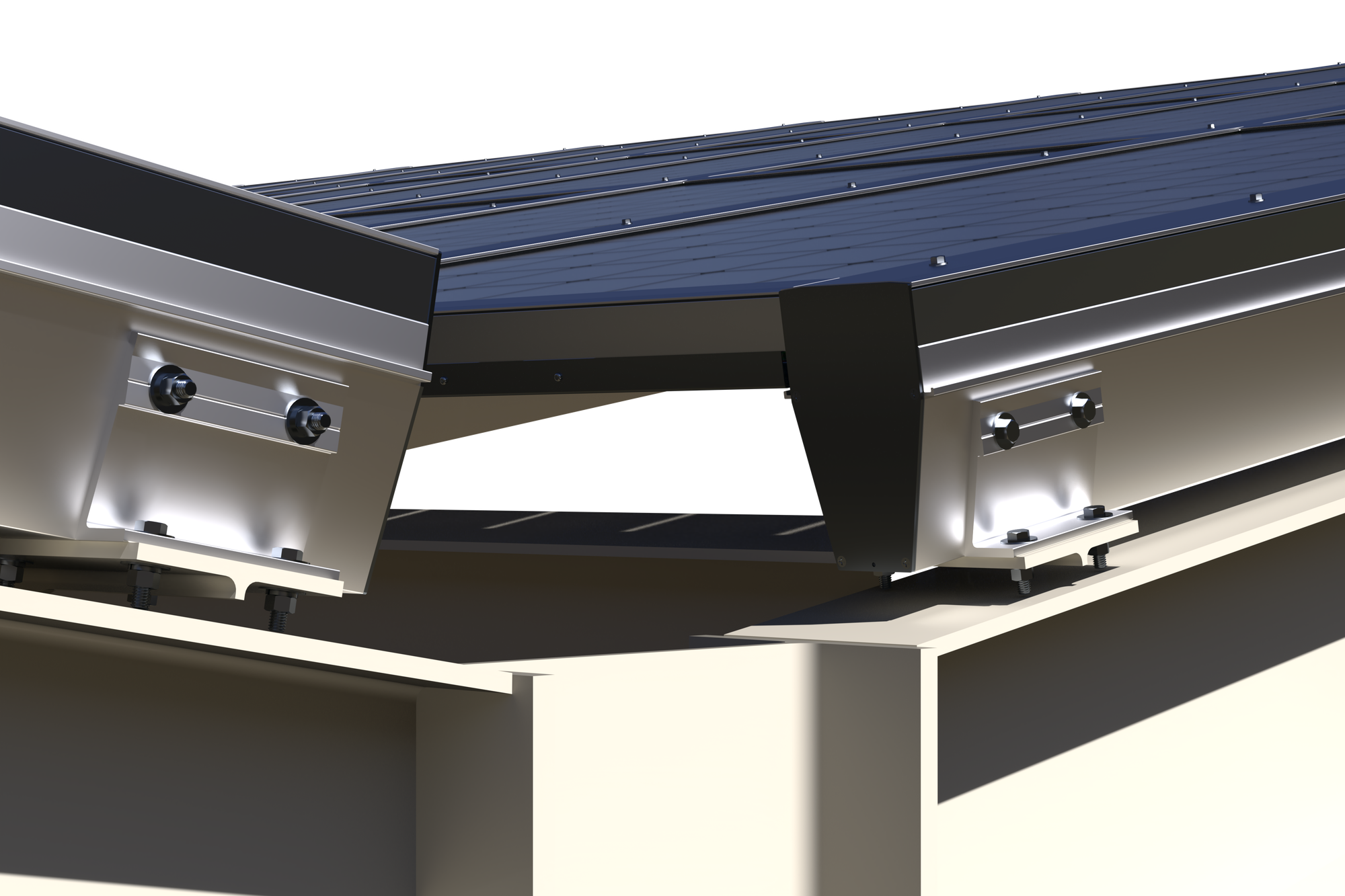

Several possible configurations: cantilever, double tilt (‘Y’), tilt up or down, or continuous structures.

Foundation Type

Compatible with all types of foundation (typically helical piles, driven piles, concrete foundations)

Elevation of PV Panel (from ground to bottom of panel)

Customizable, typically 12-14.5ft (3.6-4.4m). Above 14.5ft (4.4m) possible.

Grounding

Grounding device available, compliant with UL 2703 standard, certification pending

Typical Bifacial Gains Observed

5-15% (N-Type panels, on asphalt. Must be optimized and calculated per project, not a guarantee.)

No On-site Welding

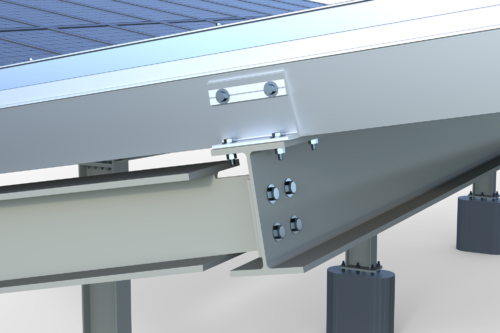

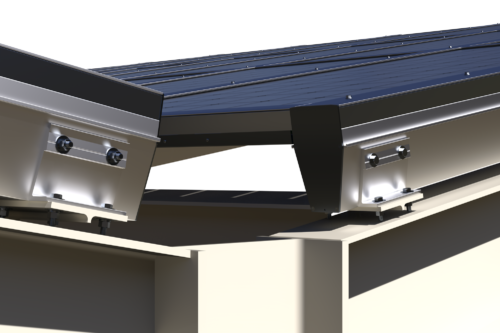

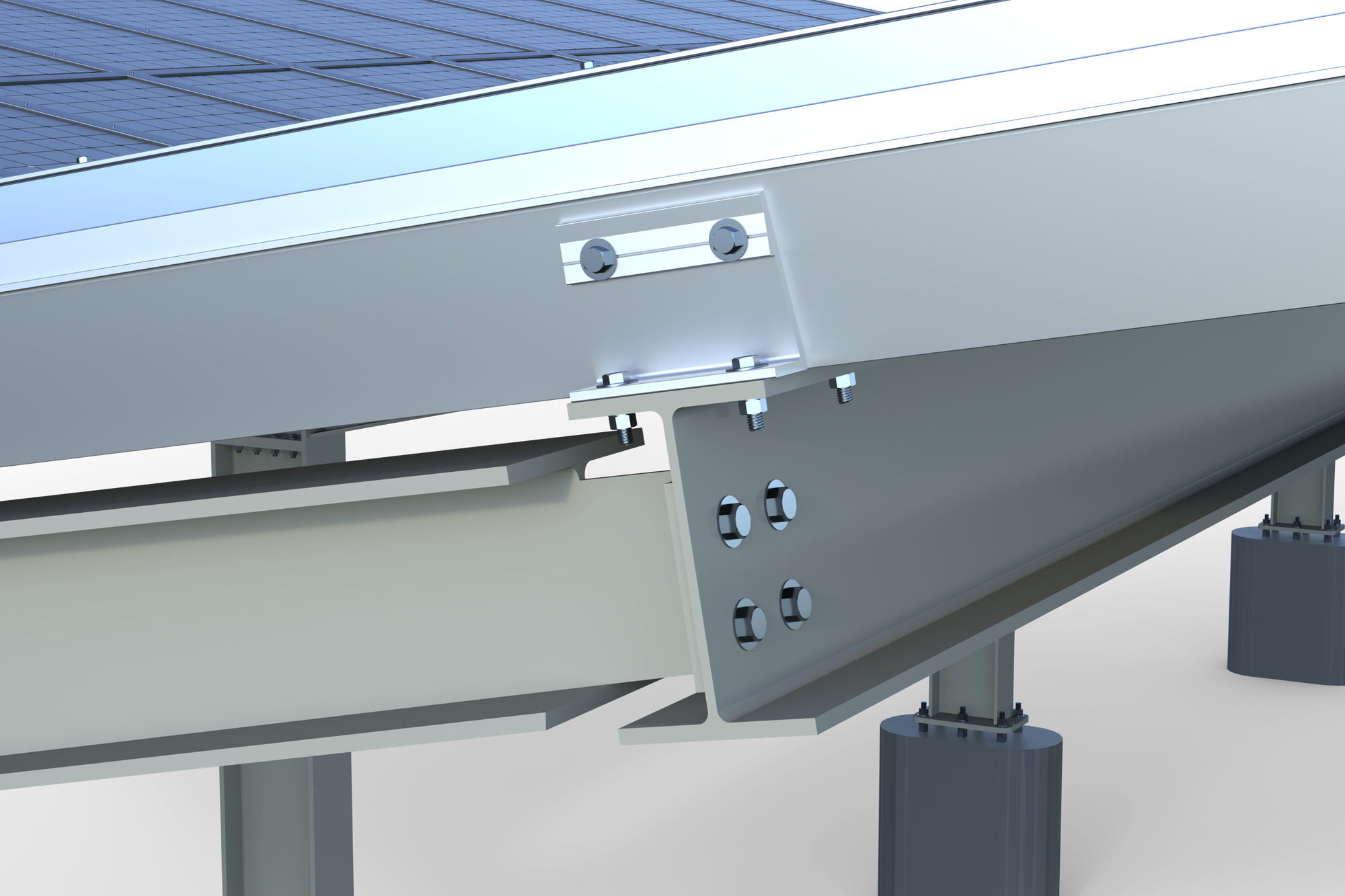

All Opsun carport systems are assembled with bolts. No welding and no cutting to be done at the installation site.

Elegant Design

All wires and junction boxes are hidden, so as not to obstruct the back of the panels and maximize bifacial gains. All system components can be powder-coated to make the structure as elegant as possible. Opsun bifacial carports take advantage of the transparency of bifacial panels to enhance aesthetics from below.

Enhance the Performance of Your Projects with Bifacial PV

Carport structures can be expensive, so it’s important to generate as much electricity on them as possible. Thanks to its structures optimized to not cast shadows on the back of the panels, Opsun enables you to get more kWh per surface area, which will help to improve the performance of your projects. Our expert teams will help you design a custom structure that meets your needs and budget.

Turnkey Engineering Services

Our team will provide expert advice to design carport structures for all types of projects, with all kinds of shapes, on all types of foundations. Our experts will help you maximize the rear gain of bifacial panels and will support you at every stage of the project, with recommendations for tilt, orientation, and positioning of the PV panels.

Advantages

IDEAL APPEARANCE WITH BIFACIAL PANELS

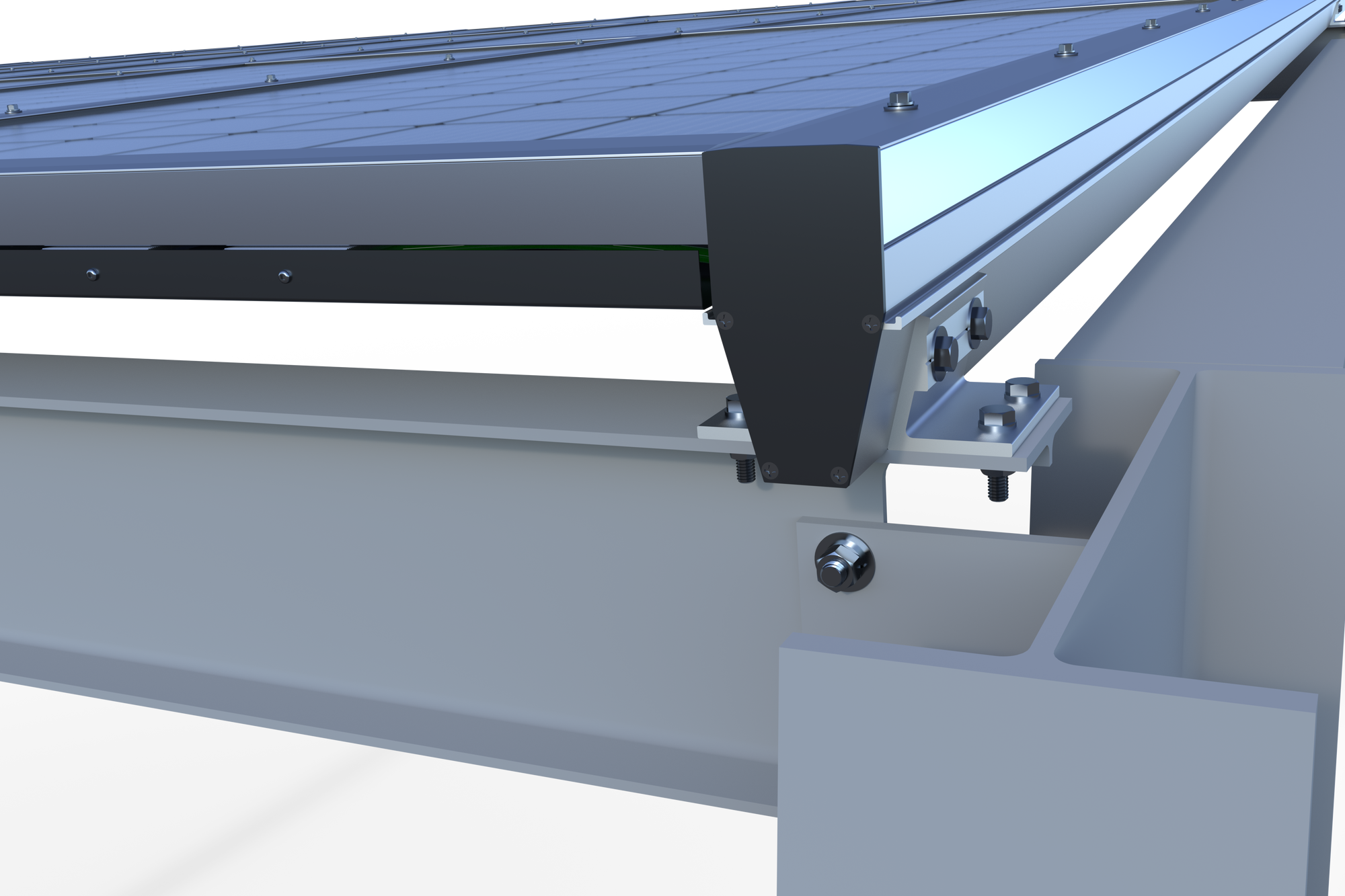

Panel frames recessed into aluminum rails, all wires hidden, all junction boxes hidden. Transparent bifacial panels have an elegant appearance from below.

DESIGN WITH ALUMINUM RAILS

Design of 6000 series aluminum rails with 304 stainless nuts and bolts to ensure maximum durability for decades. The base structure of the carports is typically made of galvanized steel (ASTM A123) with ‘H’ beams for maximum strength.

BETTER PROTECTION OF PV PANELS

Solid rails support PV panels along their entire length, limiting twisting and movements that can lead to performance degradation of PV panels.

UL 2703

Grounding in compliance with standard 2703, certification in progress.

MODULAR CONFIGURATION

The same structure can be adapted to all canopy sizes. It can also integrate any type and model of PV.

The highest standards of engineering and customer support

Opsun’s engineers use only the safest calculation methods to ensure maximum strength and durability of their structures. They use proprietary and recent (2019) wind tunnel studies from Western University, and the most recent versions of Building Codes (ASCE-10-16 and NBCC 2015, IBC 2018), as well as SEAOC PV2 guidelines with notions of the solar system’s relative dimensions compared to the roof size, to account for the most complex wind effects. The design ensures minimal deflection of the PV panels, to protect the cells, and the best finite element simulation software is used. Each component or vertical structure is subject to a unique calculation. Unique and custom solutions are found for all difficulties and the team responds quickly to events occurring during construction, (like a misplaced drain or any last-minute change).

Project-specific construction permit plans, stamped by an engineer.

For each project, you can obtain custom installation and construction permit plans tailored to the project’s difficulties, stamped by a local engineer if needed. Each step of the assembly process will be described in detail, with exact measurements relative to the actual site of the project and the necessary explanations to understand the specifics of the project.