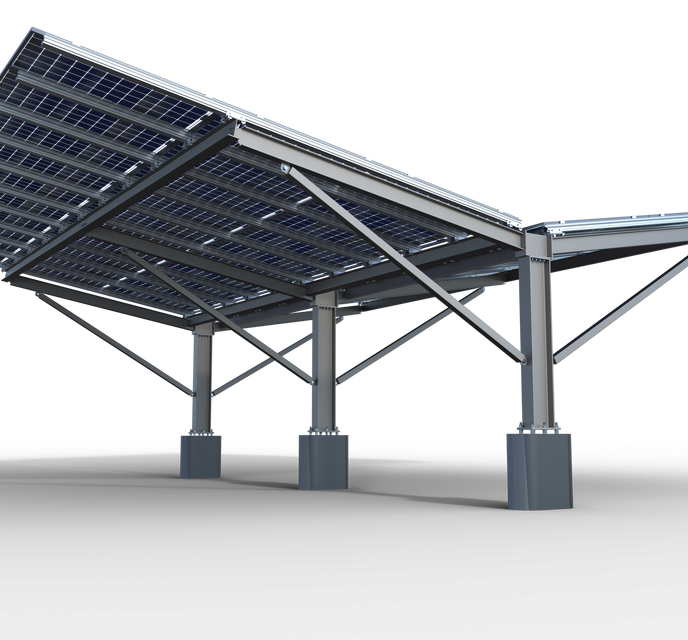

Description

Specifications

Material

Max Snow Load

Max Wind Load

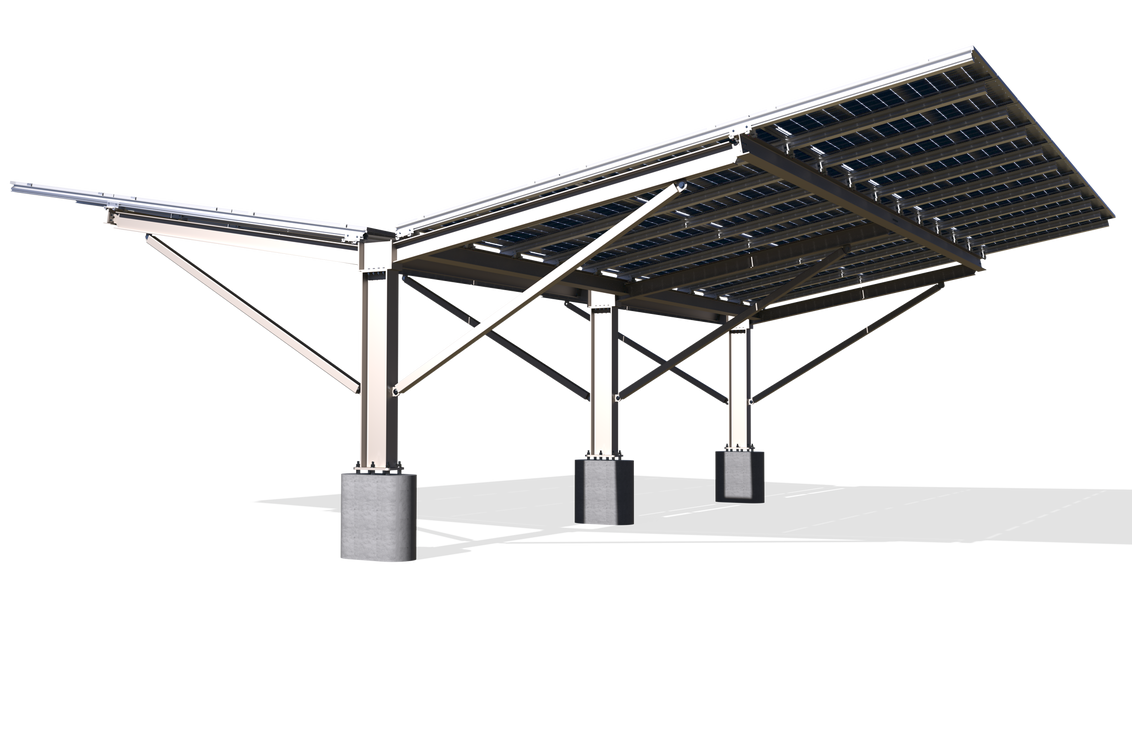

Tilt Angle

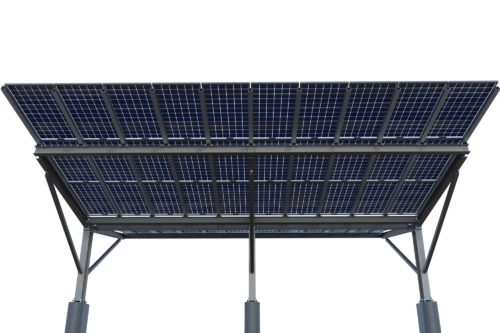

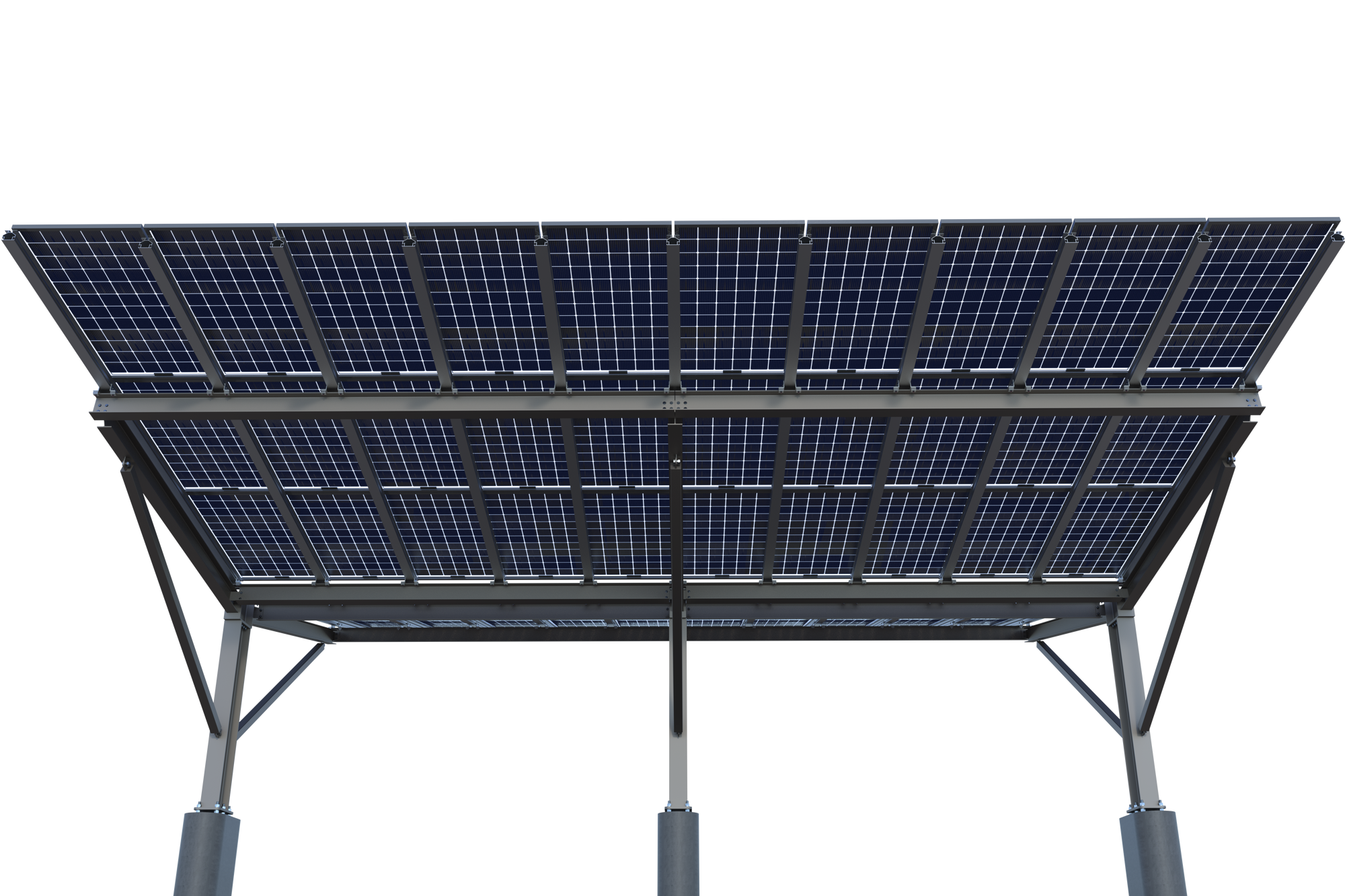

PV Panel Orientation

Solar Panel

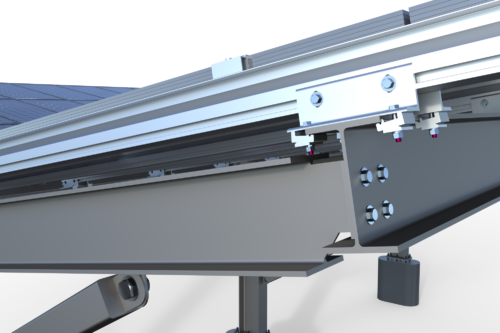

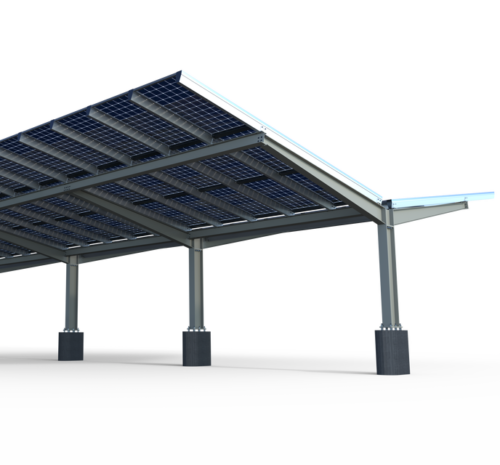

Water Management

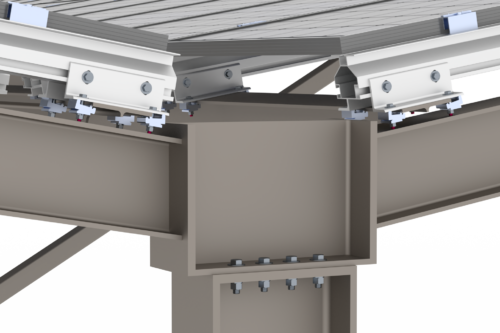

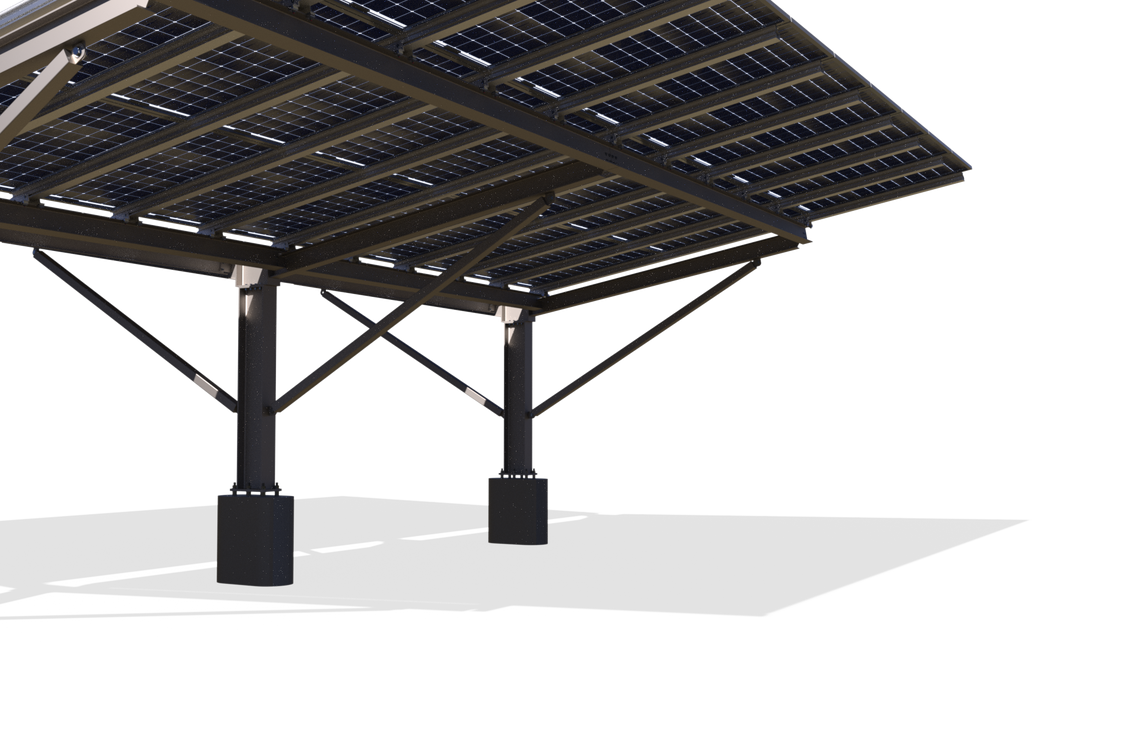

Type of Foundation

PV Panel Elevation (from ground to bottom of panel)

Grounding

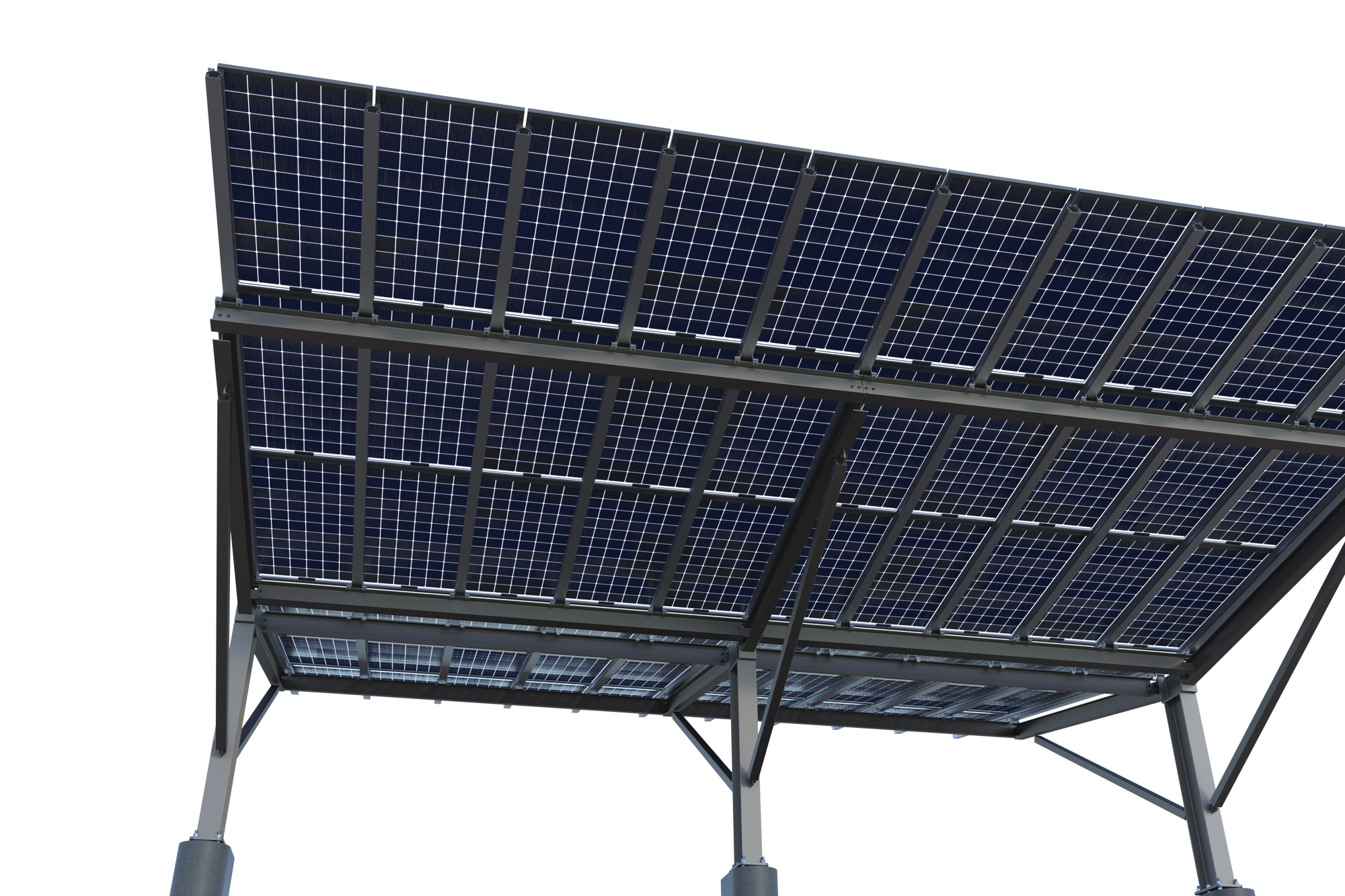

Bifacial Gains

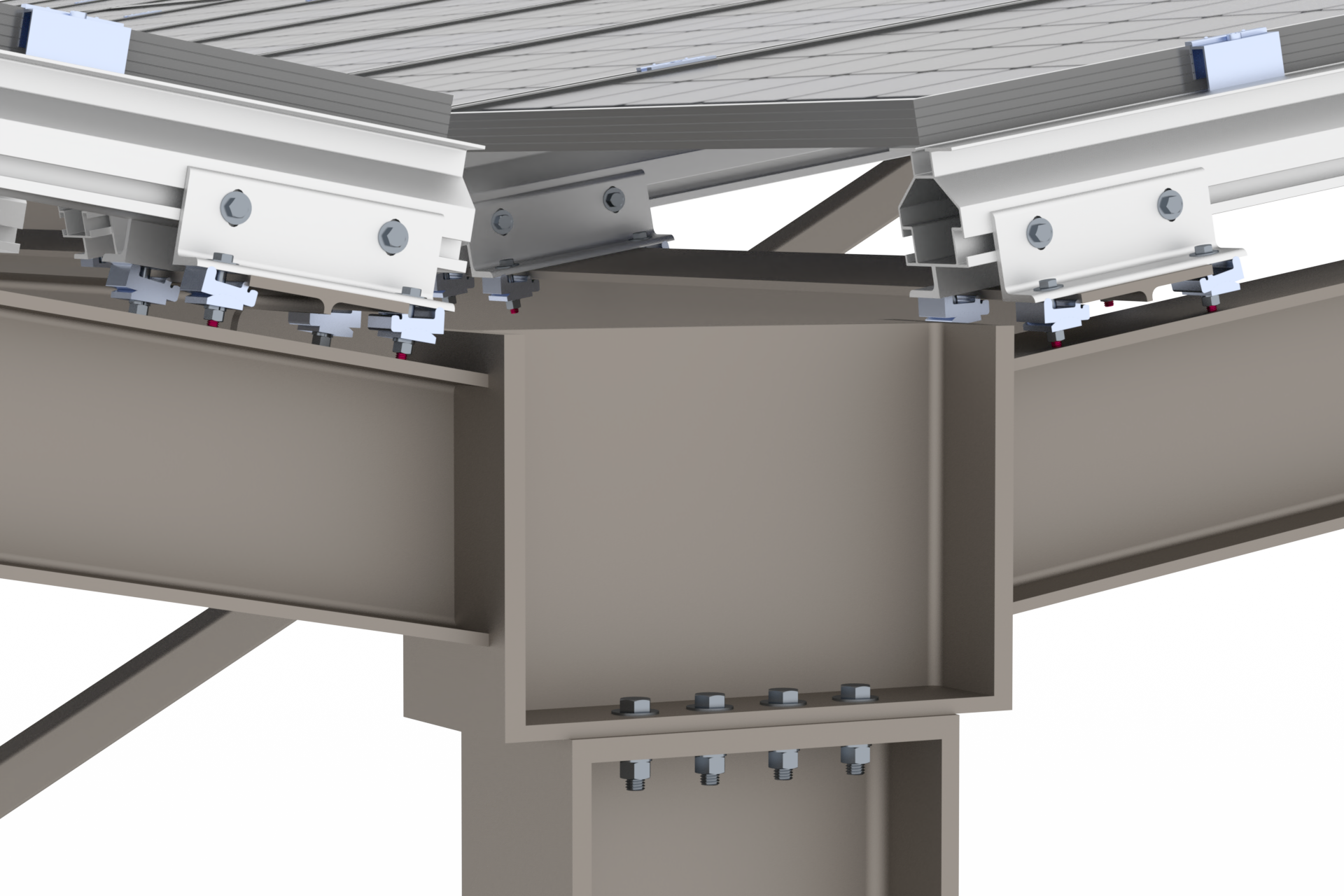

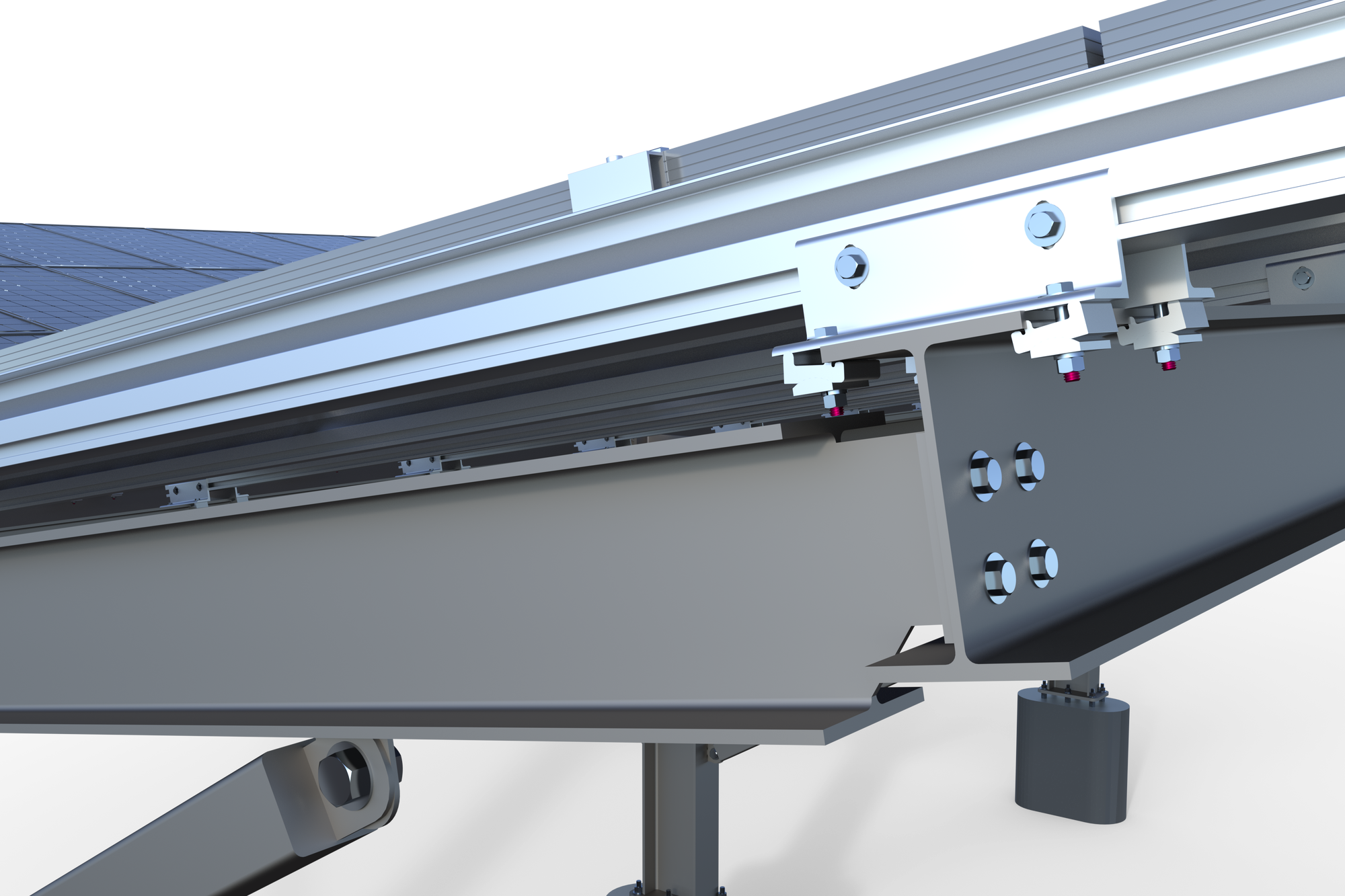

No Welding On-Site

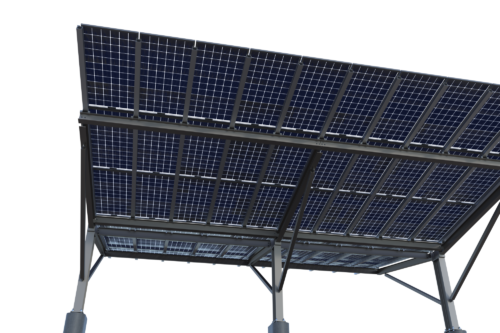

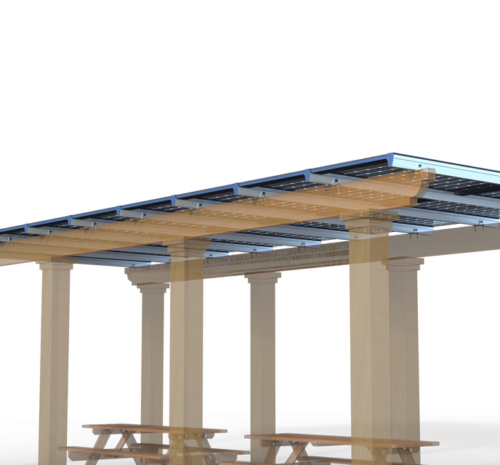

Elegant Design

Sustainable Design

Turnkey Engineering Services

Benefits

Aluminum Design (PV Rails)

Aluminum Design (PV Rails)

Better protection of PV panels

UL 2703

The highest standards of engineering and customer support

Opsun engineers use only the safest calculation methods to ensure maximum strength and durability of their structures. They use recent proprietary wind tunnel studies (2019) from Western University, and use the latest versions of Building Codes (ASCE-10-16 and NBCC 2015, IBC 2018), as well as SEAOC PV2 guidelines with concepts of relative size of the solar system to the roof dimensions, to account for the most complex wind effects. The design ensures minimal deflection of PV panels to protect the cells, and the best finite element simulation software is used. Each component or vertical structure undergoes a unique calculation. Unique and custom solutions are found for all difficulties and the team responds quickly to events occurring during construction, (such as a mispositioned drain or any last-minute change).

Project-specific construction permit plans, stamped by an engineer.

For each project, you can obtain tailored installation and construction permit plans adapted to the project’s challenges, stamped by a local engineer if necessary. Every step of the assembly process will be described in detail, with the exact measures relative to the actual site of the project and the explanations needed to understand the specifics of the project.