Description

Specifications

Material

Max snow load

Max wind load

Tilt angle

PV panel orientation

Solar Panel

Water management

Configuration

Types of foundation

PV panel elevation

Grounding

Typical bifacial gains

No onsite welding

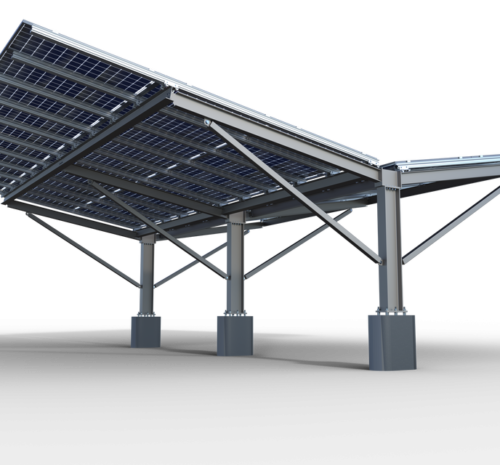

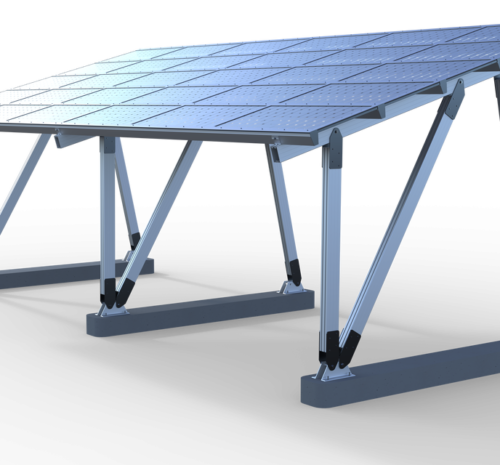

ELEGANT DESIGN

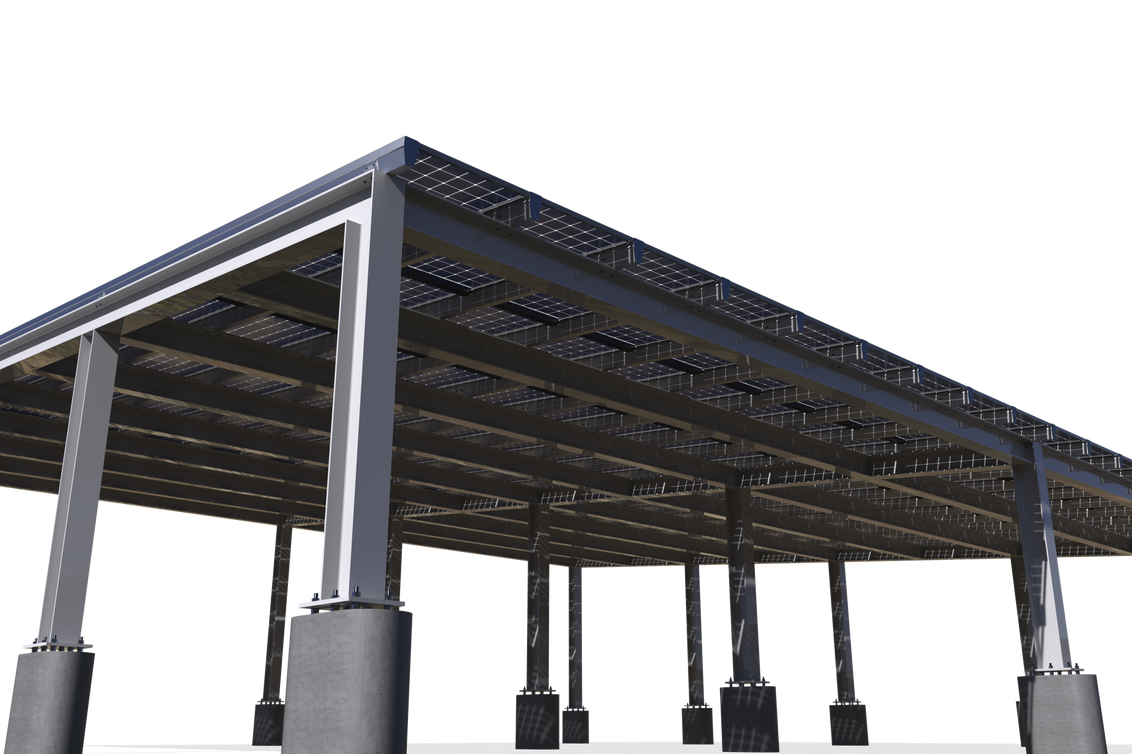

All wires and junction boxes are hidden, so as not to obstruct the back of the panels and maximize bifacial gains. All system components can be painted (powder-coated) to make the structure as elegant as possible. Opsun bifacial carports take advantage of the transparency of bifacial panels to improve aesthetics from below.

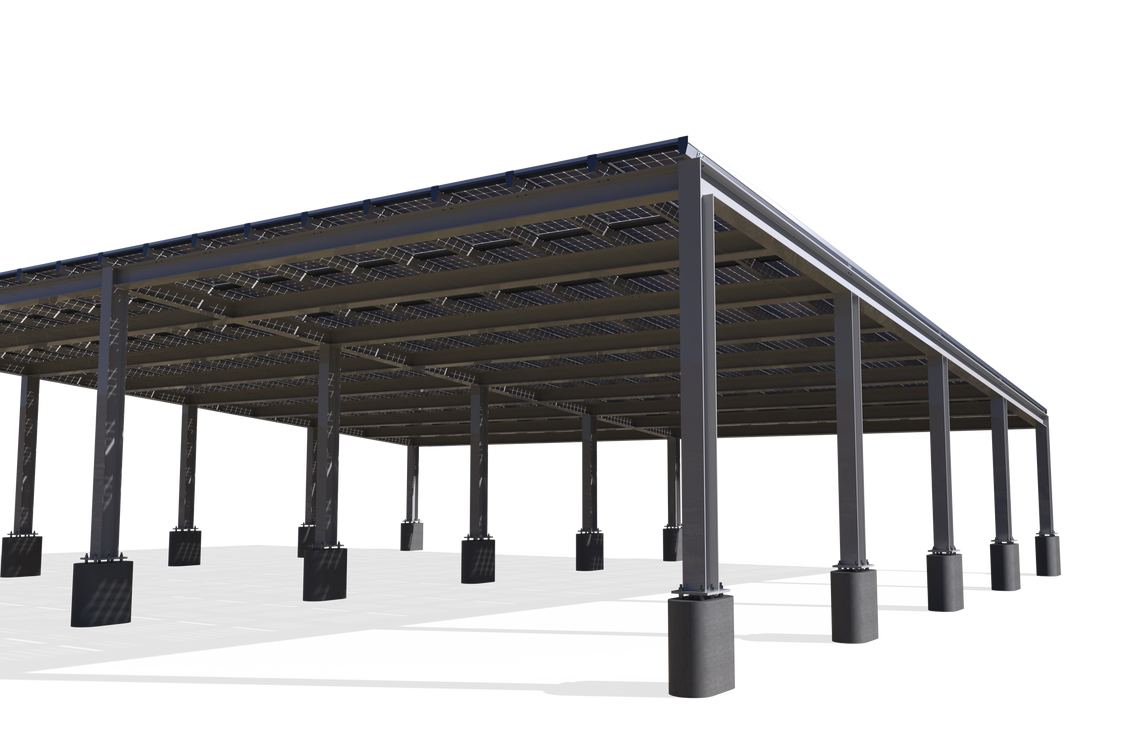

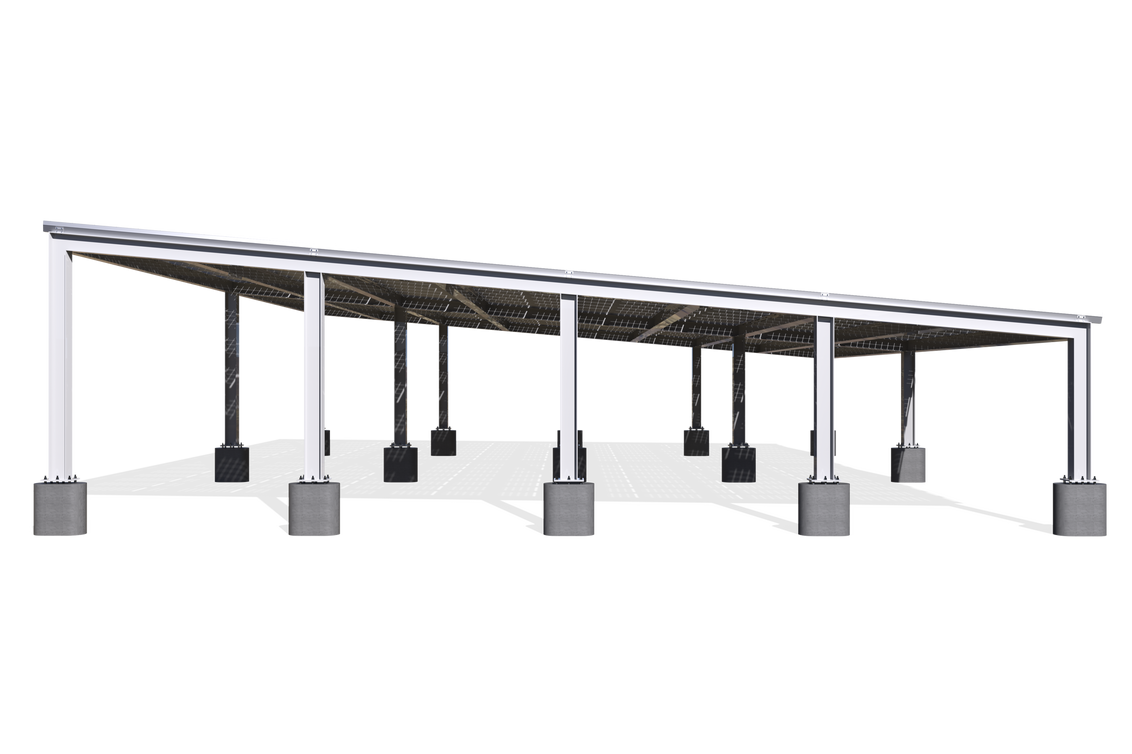

Flexible design

The Superstructure is a continuous carport system that creates a PV structure similar to a roof over a parking area. The system can manage water (optional) and silicone sealant can be added to make it waterproof. The result is a PV mounting system with maximum panel density and an elegant and avant-garde look. The structure can take any shape and size, to cover the available space in the parking area.

TURNKEY ENGINEERING SERVICES

Our team will offer expert advice to design carport structures for all types of projects, with all kinds of shapes, on all types of foundations. Our experts will help you maximize the gain from the rear side of bifacial panels and will support you at every stage of the project, with recommendations for tilt, orientation, and positioning of the PV panels.